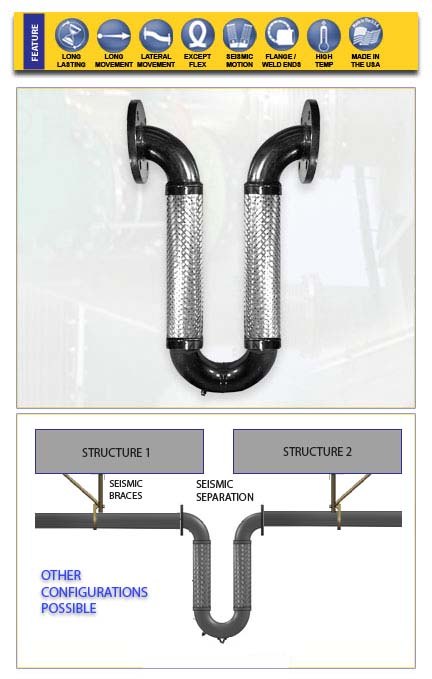

OVERVIEW: The ML Loop has become the expert method of designing for seismic movements in piping systems. The ML Loop has low spring loads, and also eliminates pressure thrust loads, in order to minimize stress on seismic bracing. And with allowed long movements in any direction, the ML Loop is ideal. Standard loop designs are supplemented by customized designs as needed.

These joints allow boilers, chillers, fan coil units, and other systems to move independently of the building.

And in seismic separations built into buildings that require pipes to cross through them, the ML Loops allow movement during an event. The loop is placed close to the separation, along with seismic braces to anchor the pipe on either side.

NFPA 13 fire sprikler guidelines are used when no other details are provided. This indicates the braces should be no further than 6ft from the separation, and the loop device no further than 2ft.

And the orientation of the ML Loop can be changed from vertical to horizontal if needed with an appropriate hanger rod.

ML Loops can be used for a wide variety of services such as steam, hot or chilled water, medical gas, natural gas, chemicals, and petroleum products. Many variations and configurations are possible. Contact the factory if assistance is required.

See the CSA/AGA ML Loop for natural gas lines.

- Independent pair of flexible legs allows considerable movement in any direction

- Low stiffness values

- Eliminates thrust load an piping anchors with the use of the stainless steel braiding

- Available in stock or custom designs

- Relatively economic design

- Accommodating larger seismic piping movements in three directions

TEMPERATURE: to 850F